The Worldwide Group, Corporation maintains four manufacturing locations where blend wax products and package them in a variety of forms. This really is additionally to some west coast terminal (which could blend bulk liquid products), west coast warehouse, and major warehouse facility in Farmer’s Valley, PA. All manufacturing locations comply with ISO 9001 standards and also have Kosher certification.

IGI’s Toronto blending facility is situated next to the wax production plant. Abilities include slab production, granulation, and the opportunity to blend vegetable waxes. In accessory for paraffin, microcrystalline wax, and petrolatum, several groups of wax blends, for example IGI’s EVACOTE line for corrugated boxes, are created only at that facility. The Toronto location also offers an emulsion blending plant, with produces products for our Enviro-Coatings line.

Titusville, Pennsylvania (USA). IGI’s Titusville plant manufactures wax slabs, granulated wax, and wax pellets. The guarana plant is really a major supplier of wax blends to be used in rubber and tire manufacturing.

Oshkosh, Wisconsin (USA). IGI’s Oshkosh facility is a state-of-the-art, 60,000 sq . ft . bulk storage, blending, and sub-dividing facility. The guarana plant provides custom wax blends in accessory for IGI’s other useful blends. Packaging abilities include slabs, pellets, and different “pouch” configurations.

Baytown, Texas (USA). Condition from the art dehumidification system for slab and pastille (pellet) manufacturing. Two “Sandvik belts” produce wax in pastille/pellet form, with packaging in bags or super sacks. Baytown can also handle drummed product, including petrolatums and highly viscous wax materials.

Resourse: http://igiwax.com/wax-blending/

Resourse: http://igiwax.com/wax-blending/

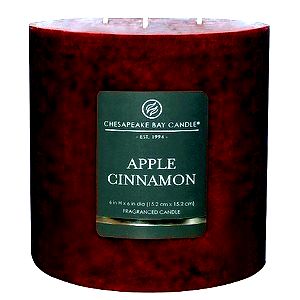

Soy Candles vs Paraffin Candles

COMMENTS:

MsApple0916: do you recommend mixing the two